MIT Work of the Future Task Force: Regions and Industries

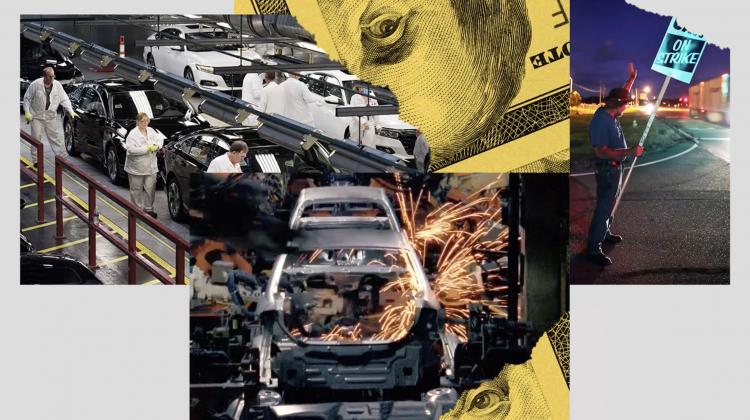

A host of institutions and organizations, as well as norms and policies, shape the relationship between technology, workers, and society more broadly. Institutions and organizations include firms, governments, labor organizations, local labor markets, as well as civic, charitable, political, and religious organizations. Norms and policies, meanwhile, shape expectations and guide behavior. Through an industry lens, we are researching trends in several industries in terms of technology adoption, changing skills requirements and overall changes to work and jobs. Advanced manufacturing and healthcare are two of the industries that are being examined. Comparative within-country, cross-region analyses as well as cross-country analysis will examine how different labor markets, communities, as well as countries, are responding to these technological advances and workplace changes.